Technical Details

| The Line’s Specifications | |

|---|---|

| Weight | About 7000kgs |

| Whole line’s dimension | About 10m x 3m x 1.5m (length x width x height) |

| Color | Main color: green |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 1-1.5mm |

| Coil width | According to products size |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | About 16 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 10-15m/min |

| Production Speed | 2m/min |

| Forming rollers material | Gcr15 mould steel, with quenched treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | Panasonic PLC and Yaskawa Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |

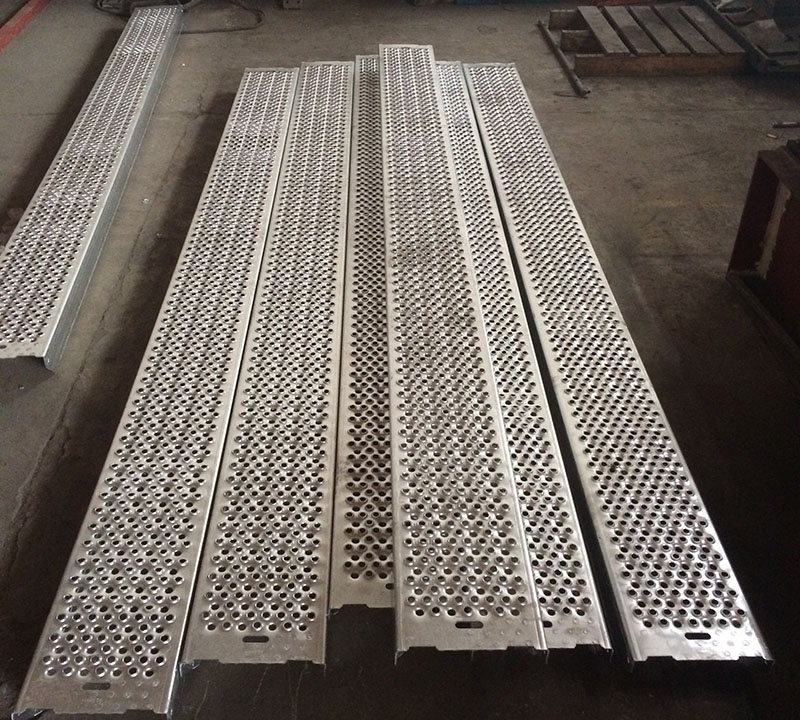

| Main Components | |

| Decoiler (manual and automatic for options) | 1 set |

| Guiding device | 1 set |

| Leveling system | 1 set |

| Punching machine | 1 set |

| Roll Forming system | 1 set |

| Hydraulic Cutting system | 1 set |

| PLC control box | 1 set |

| Hydraulic unit | 1 set |

| Run outs tables | 1 set |

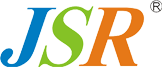

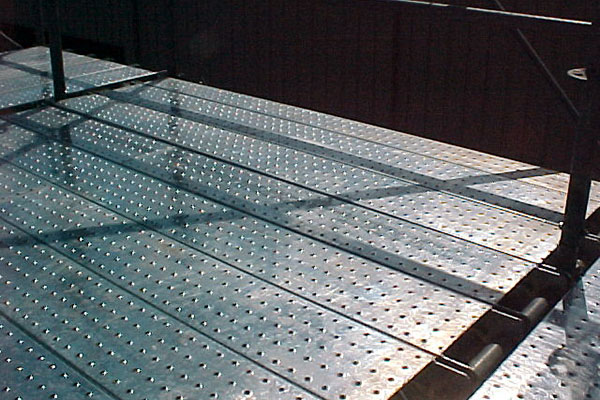

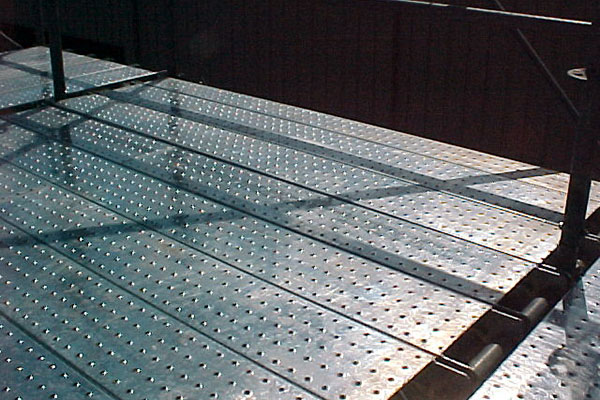

The main function of steel plank is providing the studio for the workers. There are anti-sliding hole and drainage hole on it.

JSR machinery factory manufacture scaffolding planks forming machine professionally.

If machine with punch machine, working speed about 10m/min,

If machine with hydraulic punch, working speed about 4m/min,

Gearbox can be designed in the machine for transmision.

Operate easily , work automatically with PLC controller control.

Decoiler-Punch- forming -cut - run out

JSR machinery factory manufacture scaffolding planks forming machine professionally.

If machine with punch machine, working speed about 10m/min,

If machine with hydraulic punch, working speed about 4m/min,

Gearbox can be designed in the machine for transmision.

Operate easily , work automatically with PLC controller control.

Decoiler-Punch- forming -cut - run out

-

India Customer

-

Australia Customer

-

South America Customer

Machine

-

Roll Forming Machine

- Roof & Wall Sheet Roll Forming Machine

- Step Tile Roll Forming Machine

- C & Z Purlin Roll Forming Machine

- Deck Sheet Roll Forming Machine

- Downpipe, Gutter and Fascia Forming Machin

- Shutter Door Forming Machine

- Drywall Roll Forming Machine

- Highway Guardrail Roll Forming Machine

- Storage Racks Roll Forming Machine

- Strut Channel Forming Machine

- Metal Profiles Roll Forming Machines

- Scaffolding Planks Roll Forming Machine

- Cable Tray Roll Forming Machine

- K-Span Roll Forming Machine

- Sandwich Panel Machine

- Accessories

- Metal Coils Materials

- Steel Structures Products